[x_section style=”margin: 0px 0px 0px 0px; padding: 45px 0px 45px 0px; “][x_row inner_container=”true” marginless_columns=”false” bg_color=”” style=”margin: 0px auto 0px auto; padding: 0px 0px 0px 0px; “][x_column bg_color=”” type=”1/1″ style=”padding: 0px 0px 0px 0px; “][x_raw_content]

Understanding Our business

[/x_raw_content][/x_column][/x_row][/x_section][x_section style=”margin: 0px 0px 0px 0px; padding: 45px 0px 45px 0px; “][x_row inner_container=”true” marginless_columns=”false” bg_color=”” style=”margin: 0px auto 0px auto; padding: 0px 0px 0px 0px; “][x_column bg_color=”” type=”1/2″ style=”padding: 0px 0px 0px 0px; “][x_raw_content]

Business Strategy & Consulting

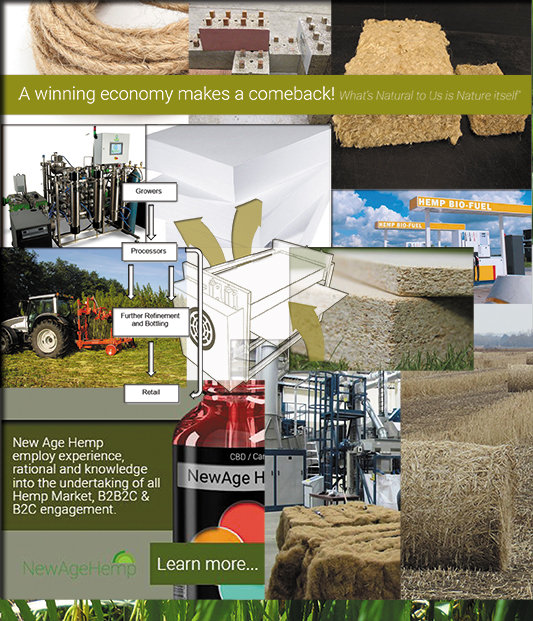

New Age Hemp’s business manifest includes the creation of local and national jobs, the stimulation this ads to our economy is tremendous.[/x_raw_content][x_gap size=”20px”][x_raw_content]Our view, is that this superior commodity will transform the quality of life around the world. Compared to similar use commodities, hemp is cultivated utilising the least amount of water and nutrients, requiring no pesticides. Hemp also has the shortest growth cycle, sequesters; the greatest level of carbon dioxide (4 times more than trees) and is unique in its ability to be grown almost anywhere in the world, sustainably.

[/x_raw_content][x_gap size=”20px”][x_raw_content]Consumer interest in our products has and still is growing globally, especially in Europe. Hemp cultivation for research purposes, is still stimulating the industry on a grand scale across the world.[/x_raw_content][x_raw_content]

Focus | Cultivation & Processing

Our main focus is to establish the largest Hemp decortication facility here in Spain. Our ability to cultivate hemp over 4,000 hectares, gives us the crop cycle factors to satisfy increasing demand.[/x_raw_content][x_image type=”none” src=”https://newagehemp.es/wp-content/uploads/2017/02/NAH-Reciprocation-2.png” alt=”” link=”false” href=”#” title=”” target=”” info=”none” info_place=”top” info_trigger=”hover” info_content=””][x_raw_content]

Immediate Markets

- CBD Dried Flower

- CBD Oils & Extracts

- Bast Fibres

- Hemp Seed

- Seed

[/x_raw_content][x_raw_content]Our new decortication plant will be the first of its kind in Europe exploiting the full potential of hemp in just one location. Our vision is to transform the hemp seed into oil and protein powder for the food industry. Utilising leaves and flowers to extract cannabidiol (CBD) for this new and rapidly emerging industry, also processing the hemp straw into fibre, hurd (wood core) and dust.[/x_raw_content][x_gap size=”0px”][/x_column][x_column bg_color=”” type=”1/2″ style=”padding: 0px 0px 0px 0px; “][x_raw_content]

Up to 45 Hectares of fertile land ready for preparation…

[/x_raw_content][x_gap size=”20px”][x_raw_content]The fibre will be further processed for the textile industry to supplement cotton and synthetic fibres. The hurd will be processed into chips to be utilised for sustainable building materials for the construction industry. The dust shall be recovered for a variety of target markets.

[/x_raw_content][x_gap size=”20px”][x_raw_content]Initial building materials produced will be utilised in the construction of the processing facilities and affordable work-force housing for the companies employees. The design and construction of the hemp processing zone will incorporate sustainable materials and technologies with the goal of achieving a near net-zero carbon footprint. These facilities will produce sustainable hemp products that will replace carbon based products and sequester Co2 permanently.[/x_raw_content][x_gap size=”20px”][x_raw_content]

New age Hemp is a company assisting the development of European hemp market from seed to store.

[/x_raw_content][x_raw_content]New Age Hemp is leading the development of it’s national hemp industry by contracting farmers in and around Europe, facilitating processing facilities, and setting up distribution through wholseale and associated vertical markets.[/x_raw_content][x_gap size=”20px”][x_raw_content]Industrial Hemp was once a dominant crop on the landscape. This hardy and renewable resource (one of the earliest domesticated plants known, with roots dating back to Neolothic Age in china) was refined for various industrial applications, including paper, textiles and cordage.[/x_raw_content][x_gap size=”20px”][x_raw_content]Over time, the use of industrial hemp has evolved into an even greater variety of products, including health foods, organic body care, clothing, construction materials, bio-fuels, plastic composites and more ( according to one source, more than 25,000 products can be made from hemp).[/x_raw_content][x_gap size=”0″][/x_column][/x_row][/x_section][x_section style=”margin: 0px 0px 0px 0px; padding: 0px 0px 0px 0px; “][x_row inner_container=”true” marginless_columns=”false” bg_color=”” style=”margin: 0px auto 0px auto; padding: 0px 0px 0px 0px; “][x_column bg_color=”” type=”1/1″ style=”padding: 0px 0px 0px 0px; “][x_image type=”none” src=”https://newagehemp.es/wp-content/uploads/2018/09/NAh-droppr-bottles-CBD.png” alt=”” link=”false” href=”#” title=”” target=”” info=”none” info_place=”top” info_trigger=”hover” info_content=””][/x_column][/x_row][/x_section][x_section style=”margin: 0px 0px 0px 0px; padding: 0px 0px 0px 0px; “][x_row inner_container=”true” marginless_columns=”false” bg_color=”” style=”margin: 0px auto 0px auto; padding: 0px 0px 0px 0px; “][x_column bg_color=”” type=”1/1″ style=”padding: 0px 0px 0px 0px; “][x_raw_content]

[/x_raw_content][/x_column][/x_row][/x_section][x_section style=”margin: 0px 0px 0px 0px; padding: 0px 0px 0px 0px; “][x_row inner_container=”true” marginless_columns=”false” bg_color=”” style=”margin: 0px auto 0px auto; padding: 0px 0px 0px 0px; “][x_column bg_color=”” type=”1/1″ style=”padding: 0px 0px 0px 0px; “][x_raw_content]

Once our decortication facility is completely operational the extension of our business plan includes the following vertical market opportunities.

[/x_raw_content][/x_column][/x_row][/x_section][x_section style=”margin: 0px 0px 0px 0px; padding: 0px 0px 0px 0px; “][x_row inner_container=”true” marginless_columns=”false” bg_color=”” style=”margin: 0px auto 0px auto; padding: 0px 0px 0px 0px; “][x_column bg_color=”” type=”1/1″ style=”padding: 0px 0px 0px 0px; “][x_raw_content][/x_raw_content][/x_column][/x_row][/x_section][x_section style=”margin: 0px 0px 0px 0px; padding: 45px 0px 45px 0px; “][x_row inner_container=”true” marginless_columns=”false” bg_color=”” style=”margin: 0px auto 0px auto; padding: 0px 0px 0px 0px; “][x_column bg_color=”” type=”1/2″ style=”padding: 0px 0px 0px 0px; “][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/Hurd.jpg” alt=””]

1st Pass Refining

Decorticated hemp straw generates Hurd Fibre, which comes from stalk.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/hurd-based-building-blocks.jpg” alt=””]

Hemp Building materials

A bio-composite material consisting of hurd, lime, water and binder. This product is expected to be a primary driver of the hemp fibre industry as large volumes of hurd stock are required by the emerging bio-building sector.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/BAST-Bedding-Material-for-animals.jpg” alt=””]

Hemp Bedding materials

Owed to it’s superior absorbency properties and low dust content. hurd is widely recognised as a high per formance bedding for farm animals (particularly horses) and pets.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/BAST-Absorbents.jpg” alt=””]

Absorbents made from Hemp

Hurd has application in the oil and gas industry as a high capacity material used for cleaning up spilled drilling muds and other harmful effluents.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/BAST-Particle-Fibre-Boards.jpg” alt=””]

Hemp particle Boards

Hurd may serve as a high grade wood replacement in some appplications, I.e furniture making.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/BAST-1.jpg” alt=””]

2nd/3rd pass Refining

Decortication of hemp straw results in two major types of fibre, Hurd and Bast. While both types of fibre can potentially be used in a plethora of industrial applications.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/ii-refined-bast-fibre-bales.jpg” alt=””]

Bast Fibre Bales

Few hemp fibre based products appear to have the potential to be successfully commercialised on the European marketplace.

[/x_promo][/x_column][x_column bg_color=”” type=”1/2″ style=”padding: 0px 0px 0px 0px; “][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/fibre-mats-and-their-biocomposite.jpg” alt=””]

Hemp Plastic Bio-Composites

These can be made using compression and injection moulding processes. For example, Bast fibre mats infused with resins replace fibreglass in composites used by the automotive industry, making hemp parts lighter and easily recyclable.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/example-of-injection-moulded.jpg” alt=””]

Hemp Bio-Composites Injection Moulding

Similar advantages are offered from Bast Fibre in injection moulding products. Some truck canopies are made of hemp fibre mats infused with plastic resins.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/hemp-fibre-yarn-pillow.jpg” alt=””]

Textiles from Hemp Fibre

The oldest application of bast fibre is re-gaining in popularity. Premium prices should be achieved for appropriately prepared straw suitable for textile applications. Hemp`for high quality textile applications often requires more demanding crop management and specialised decortication processing lines.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/different-grades-of-insulation.jpg” alt=””]

Insulation made with Bast Fibre

Natural fibre materials provide good thermal protection. They are environmentally friendly and do not emit toxic, often allergenic chemicals found in synthetic insulation materials.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/BAST-fibre-high-grade-paper.jpg” alt=””]

Bast High Grade Paper

Revival of hemp cultivation will make available feedstocks for manufacturing of speciality low volume, high value paper products.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/BAST-fibreTwine-and-rope.jpg” alt=””]

Twine, Rope & Upholstery

Lower grade, coarser Bast Fibre can be used for the production of tough fabrics and cordage.

[/x_promo][x_promo image=”https://newagehemp.es/wp-content/uploads/2018/09/Hemp-Dust-Biofuel-Pellets.jpg” alt=””]

Hemp Dust

Decortication of hemp stalks generates 10%-15% of non-fibrous dust particles. After pelletization this bi-product that has high heating value can be marketed as environmentally friendly fuel.

[/x_promo][/x_column][/x_row][/x_section][x_section style=”margin: 0px 0px 0px 0px; padding: 45px 0px 45px 0px; “][x_row inner_container=”true” marginless_columns=”false” bg_color=”” style=”margin: 0px auto 0px auto; padding: 0px 0px 0px 0px; “][x_column bg_color=”” type=”1/1″ style=”padding: 0px 0px 0px 0px; “][x_raw_content]

New Age Hemp, promotes ‘whole plant processing & usage’

[/x_raw_content][/x_column][/x_row][/x_section]